ICAR-National Institute of Natural Fibre Engineering and Technology is a premier institute under Indian Council of Agricultural Research, New Delhi and dedicated to the cause of natural fibres leading to the diversified use and industrial growth.

This research institute was initially set up by the Indian Central Jute Committee, Government of India on the recommendation of the Royal Commission on Agriculture in 1936 at Calcutta. It was officially established as a research institute on January 3, 1939 by Lord Linlithgow, the then Viceroy and Governor- General of India. In 1965, the institute became a constituent unit under the centralized administrative control of the Indian Council of Agricultural Research (ICAR), New Delhi and named as Jute Technological Research Laboratory (JTRL). JTRL had prospered with multifarious dimensions and developed many indigenous technologies for jute as well as for allied fibres. In reorganization of R&D activities, ICAR had renamed the institute as “National Institute of Research on Jute and Allied Fibre Technology (NIRJAFT)” and also declared as centre of excellence in late nineties. ICAR-NIRJAFT has carried out basic and applied researches related to post harvest processes of jute and allied fibres such as mesta, linseed/flax, sisal, ramie, banana, sunnhemp, pineapple leaf, dhaincha, coconut fibre , yak hair, Indian wool fibre, silk fibre and other lesser known long vegetable fibres. Being a lead research institute which was working in knowledge transfer and economic development activities for all natural fibres, the council in its 245 Governing Body (GB) meeting held on November 10, 2018, promoted the institute to work continuously in the area of natural fibres and accordingly renamed as ICAR-National Institute of Natural Fibre Engineering and Technology (ICAR-NINFET).

Journety of NINFET: From Laboratory to National Institute

ICAR-NINFET is situated on the southern fringe of the metropolis of Kolkata. It was originally established over an open area measuring 9150 m2. Later on it has undergone both horizontal as well as vertical expansion. Today the Institute has 3 major research and administrativebuildings, Training Hostel, Guest House and residential quarters. During the eight long decades of its existence, NINFET has flourished multifarious dimensions and developed many indigenous technologies for jute as well as allied fibres. In recognition of its ever increasing activities and looking into the national importance of natural fibres, the mandate of the Institute widened further with its new name.

Vision, Mission & Mandate of ICAR-NINFET:

Vision

To uphold the cause of jute and allied fibres in favour of farmers, trade and industry keeping in view the prevalent global scenario and bring back the glory of the golden fibre with socio-economic uplift.

Mission

Utilization of jute and allied fibres in wide and diverse areas by exploiting the intrinsic and advantageous properties of the fibres and converting the demerits whatsoever into merits by application of scientific tools through development of technologies, products and process for the benefit of farmers and industries both the large and small scale.

Mandates:

Focus

To accomplish the VISION and MISSION for holistic development of natural ligno-cellulosic fibre sector starting from production, processing, marketing and entrepreneurship development, ICAR-NINFET is engaged for more than eight decades with the following strategic areas involving modern cutting edge frontier research technologies.

• Cost-effective production, processing and value addition to jute and allied fibre and better technologies for breakthrough in promising fields of geo-textiles, agro-horticultural, bio- and green-composites etc., as well as in exploiting the utilization potential of their agro-residues.

• Developing low-cost and eco-friendly technologies for extraction of fibres with low or no-water requirement in view of water scarcity.

• Use of nonconventional and renewable energy for mechanical and chemical processing of fibres

• Instrumentation for quality management of fibre, Development of finer yarn from jute and jute blends, new process line for spinning and nonwoven machineries

• Development of jute and allied fibre based bio- and green-composites, non-yellowing hand-made paper from jute whole plant, green technologies utilizing eco-friendly processing and finishing chemicals for making value added and diversified jute and allied fibre products

• Innovative cutting edge technologies intervention with biotechnology and nanotechnology for development of value added products and nanocomposites from jute and allied fibres

• Efficient utilization of under-exploited fibres like banana, coir, sisal, pineapple leaf fibre, ramie, etc., and their agro-residues through value chain system

• Use of biomass, after extraction of fibre, for preparation of fine chemicals.

• Extraction and utilization of lignin and its derivatives for industrial use.

• Development of human resource and accelerate dissemination of technologies, entrepreneurship development through business incubation, cluster development to promote livelihood through marketing of innovative natural fibre products.

Institute Vision 2030 documented a futuristic look in the field of jute and allied fibres in the domestic and global context and likely scenario in 2030 in view of the challenges of population increase, water crisis, climate change and growing environmental consciousness which has created new opportunities in the domestic and global market for development of natural fibres to meet the consumer demand in diverse fields. This document provides a road map to support the vision direction, identify the major barriers to progress and focus attention on priority research areas. So, the specific reasons to prepare long term vision of ICAR-NINFET are as follows:

• Vast opportunities created or likely to be created in global market for sustainable and eco-friendly development with the advancement of science and technology, how to benefit the natural fibres sector from them.

• Time gap between researches and its output and adaption with “business as usual” approach delaying delivery of output and outcome.

• To increase relevance of jute and allied fibres sector in the national economy, carbon foot print, eco-friendly society and food security.

• To promote new programme with innovative ideas and thinking to achieve breakthrough in the sector utilization of the most advanced technologies, and continuing discussions at the highest intellectual levels.

• Diversification of growth and products

In order to draw road map for next 30 years, institute feel to come out futuristic vision 2050 having newer area of research, need of infrastructure and mandate of institute to serve the nation with effective and comprehensive manner

An ISO 9001:2015 Institute:

ICAR-NINFET is an ISO 9001:2015 Institute and achieved the QMS for another three years starting from January 6, 2020 to January 5, 2023. An effort is being made to get recognition/ status of NABL Accredited referral Laboratory on Natural Fibres in near future

Location

The institute is located on southern fringe of Kolkata city, West Bengal, India, at 12, Regent Park near to Ranikuthi, Tollygunge.

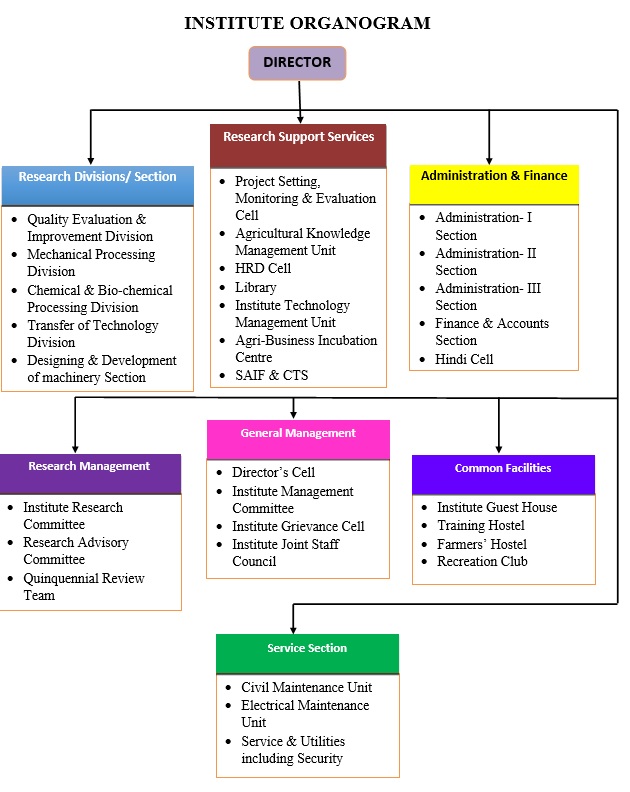

The institute functions under the Director who is responsible for all matters related to institute including day to day function, liaison with ICAR and other institutes and government bodies. He also supervises the research divisions as well as service sections and coordinates with various committees. The general management comprises Institute Management Committee (IMC), Institute Joint Council (IJC) and Grievance Cell (GC) while the research is monitored by Research Advisory Committee (RAC) and Institute Research Committee (IRC). There are four research divisions and five sections / cell besides finance and administrative departments.

Research & Development Units at ICAR-NINFET

The R&D programs of the institute are implemented through the following four divisions & different sections.

i. Quality Evaluation and Improvement (QEI) Division

QEI division engages in the area of fibre extraction, Jute retting: microbial retting, formulation of retting powder etc, evaluation, quality assurance and grading. Up gradation of quality, evaluation of physiochemical properties of jute and allied fibres are the major contributions ofthis division including extraction of useful chemicals from agricultural by-products of fibre crops.

ii. Mechanical Processing (MP) Division

MP division carries out basic and applied research on mechanical processing, quality control and productdevelopment from naturalfibres. Improvement of process, productivity & product quality; design &development of product; quality assessment on geo-textile, agro-textile, apparel,packaging, Technical textiles are the main areas of research of this division.

iii. Chemical and Biochemical Processing (CBP) Division

CBP division works in the area of chemical/ biochemical processing, quality control and productdevelopment from all natural fibres. It has major contributions on pulp & paper; bleaching, dyeing &finishing; particle &fibre board; composites from jute and allied fibres. Advanced textile processing andbiomass utilization are also important areas.

iv. Transfer of Technology (TOT) Division

ToT division disseminates the institute's technologies, develops entrepreneurship providing the technicaltraining and capacity building, arranges the front line demonstrations and participates in differentexhibitions, fairs and Mela for promoting the developed technologies. It is also developing the projectprofile of viable technologies and rendering technical assistance for incubators.In addition to the above division, the following sections are assisting to carry R&D works in the institute.

v. Designing & Development of Machinery Section

A dedicated design, development of machineries R & D section assists in design and development or modification of machinery/prototype, equipment, and instruments for fibre extraction, processing and value addition of the products. The section also provides support for maintenance of equipment & instruments of Scientific divisions.

All India Network Projects (AINP)

The Institute has been inducted as one of the Centres of All India Network Project on Jute & Allied fibres (AINPJAF) for testing and quality evaluation of jute & other allied fibres since 2020.

Priority setting, Monitoring & Evaluation Cell

PME cell helps to monitor the R&D programs of the institute. It is responsible for convening meetings of the Institute Research Council, Research Advisory Committee, and compiling the monthly, quarterly, half-yearly and annual technical reports of the institute. This unit also coordinates in technical inquiries from the council from time to time. The cell also responsible of coordinating Memorandum of Understanding.

Human Resource Development (HRD) Cell:

The Institute runs a dedicated HRDcell for promoting the activity for encouraging the scientists as well as other staff members to undertake training, participate in seminars, conferences, symposia etc.

Agricultural Knowledge Management Unit (AKMU):

Agricultural Knowledge Management Unit (AKMU) is committed to promote implementation of Institute’s ICT driven technology and information dissemination system for quick, effectual and cost-effective delivery of messages to all the stakeholders in agriculture.

A dedicated Sophisticated Analytical Instruments Facility (SAIF) has been created with a modern laboratory facility. Needy persons, students and researchers working in different institutions can utilize these facilities on charge basis. Commercial Testing facility provided by institute is also coordinated by this Centre.

Library:

Library acts as a centre of repository for scientific and technological information of jute & allied fibres including other ancillary disciplines by maintaining a large number of books, journals, reports, reprints, pamphlets. ICAR-NINFET library has the best archive on natural fibre in the World. It has fully digitized automated library covering multiple disciplines.

Scientific Manpower of the Institute: The Multidisciplinary Amalgamation

The Institute has scientific manpower of multi- disciplinary areas. It has a unique combination of scientists from Textile Manufacture, Textile Chemistry, Agricultural Physics, Bio-chemistry, Organic Chemistry/ Agricultural Chemicals, Agricultural Micro-biology, Farm Machinery and Power, Agricultural Structure & Process Engineering, Agricultural Economics, Farm Machinery & Power, Computer Application in Agriculture.

The existing staff strength of the Institute over the sanctioned posts is presented in the following table.

| Category | Sanctioned Strength (Regular) | In-Position | Vacant |

| Scientific | 45 | 26 | 19 |

| Technical | 60 | 42 | 18 |

| Administrative | 33 | 19 | 14 |

| SSS | 23 | 15 | 8 |

| Total | 161 | 102 | 59 |