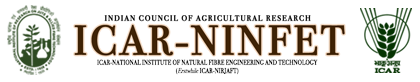

Visit this link to listen https://akashvani.gov.in/radio/live.php

Vigilance Awarness Week Concluded

Workshop with representatives from FPOs/FPCs/NGOs

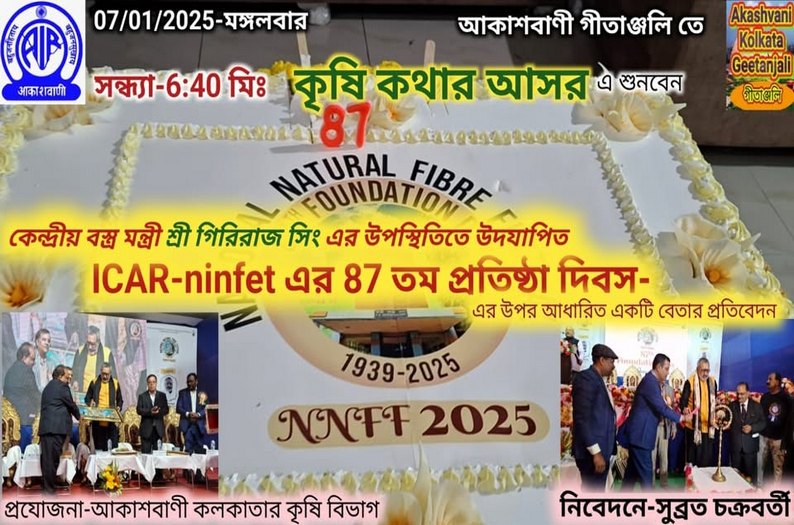

ICAR-NINFET singed MoU with FDDI

Closing ceremony of Swachhata Hi Sewa

हिन्दी पखवाड़ा समारोह– 2024

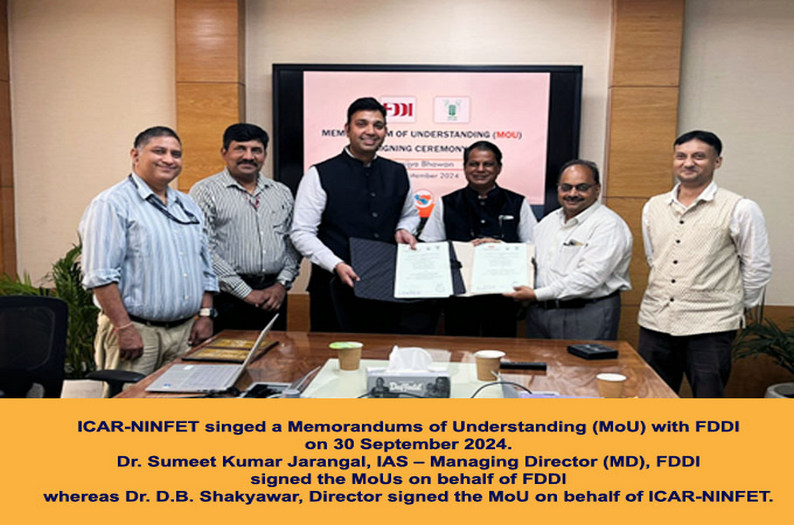

राष्ट्रीय हिंदी वैज्ञानिक संगोष्ठी, 2024

ICAR- NINFET celebrated 19th Parthenium Awareness Week during August 16-22, 2024

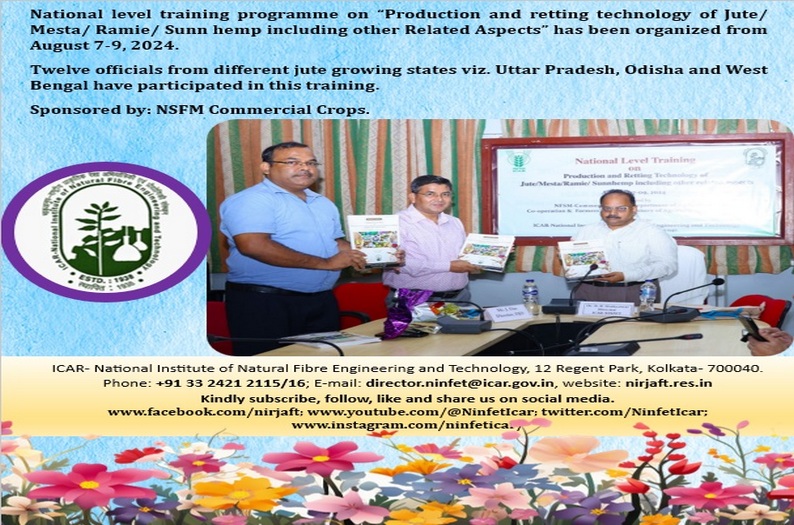

NSFM sponsored National Level Training Programme

Celebration of National Handloom Day

Training Programme on ‘Manufacturing of Jute Hand Bag and Jute Handicrafts from Jute’ at Katihar, Bihar

Training Programme on ‘Manufacturing of Jute Hand Bag and Jute Handicrafts from Jute’ at Katihar, Bihar

Workshop on ‘Mechanical Extraction & Retting of Hemp Fibre for Development of Sanitary and Textile Products using ICAR-NINFET Technologies’ at Rishikesh, Uttarakhand

ICAR-NINFET Technologies Released on the occasion ICAR 96th Foundation Day

Skill development training on “Basic and strategic research on Manufacturing of jute fibres and their residues”

Business Meet on E- Commerce Platform Creation for Eco-Friendly Products Made of Natural Fibre & Allied Materials, June 14, 2024

Skill Development Training on Manufacture of Jute Handicrafts and Bag, June 13, 2024, Kolkata

बेटी बचाओ बेटी पढ़ाओ

National workshop on "Jute- Production, Marketing and Utilization Strategies"

National Level Training on “Production and Retting technology of jute/mesta/ramie/sunnhemp includes other related aspects”

Signing of MoU between NINFET & JCI at Bharat Tex-2024, New Delhi

Inauguration of EDP at ICAR-NINFET, Kolkata

Director with NINFET Staff@ I Love NINFET

Special Swachhta Abhiyan

Visit of Dr. SN Jha, DDG (AE) at ICAR-NINFET, Kolkata

Visit of Dr. SN Jha, DDG (AE) at ICAR-NINFET, Kolkata

Skill Development Training on Manufacture of Jute hand Bag, 2024

Participation in TEZ 2023

Skill Development Training on Jute Diversified Products

ICAR-NINFET, Kolkata Celebrates its 86th Foundation Day

ICAR-NINFET, Kolkata Celebrates its 86th Foundation Day

ICAR-NINFET, Kolkata Celebrates its 86th Foundation Day

ICAR-NINFET, Kolkata Celebrates its 86th Foundation Day

Valedictory function of Swacchta Pakhwada

Celebration of National Farmers' Day

Vigilance Awareness Week, 2023

ICAR-NINFET organized “World Soil Day”

Student Awareness cum Sensitization Programme at Calcutta Institute of Engineering and Management (CIEM), Kolkata

Certificate Distribution Programme of Skill Development Training

Training Programme on Handloom Product Development from Kans Grass at Uttar Dinajpur

Training on “Manufacture of Jute Diversified Products”

हिंदी पखवाड़ा समापन समारोह

ICAR- National Institute of Natural Fibre Engineering and Technology celebrated 154th Birth Anniversary of Mahatma Gandhi in its campus

Five day training on Handloom Product Development from Kans Grass at Shergram, Kaliyaganj, Uttar Dinajpur

The pledge taking ceremony for ‘Single Use Plastic ban was organized at ICAR-NINFET on September 26, 2023

“प्राकृतिक संसाधनों से देश के उन्नयन विकाश में आधुनिक तकनीकों का योगदान” विषय पर राष्ट्रीय हिंदी वैज्ञानिक संगोष्ठी

Training cum workshop Programme on Nettle fibre Extractor at RRS, UBKV, Kalingpong

Awareness-cum-Sensitization Programme at Uluberia Govt Polytechnic, Howrah

Three Months Short Course Training Programme on “Manufacturing/Weaving of Woollen Items” at ICAR-NRCY, Dirang

FLD on NINFET- Sathi Retting Technology of Jute and visit of the Committee constituted by Ministry of Agriculture and Farmers Welfare, GoI on the Status of Jute

ICAR-NINFET organized Awareness cum Sensitization Programme on ICAR Institute Activities at Bhola Paswan Shastri College of Agriculture at Purnea, Bihar

MoA on contract research in the area of Extraction of keratin and Development of biochar and activated carbon

ICAR-NINFET organized Training Programme on “Manufacturing of Handicraft Items from Nettle & Bhimal Fibres

Exposure visits of artisans from Odisha to ICAR-NINFET, Kolkata

ICAR-NINFET Celebrated 9th National Handloom Day

Training programme on Computer-Aided Design organized by ICAR-NINFET,

One Day Interactive Meeting-cum-Brainstorming session organized

One Day Interactive Meeting-cum-Brainstorming session organized

One Day Interactive Meeting-cum-Brainstorming session organized

One Day Seminar organized at ICAR-NINFET, Kolkata

Training Program On “Instrumental Jute grading as per NABL requirements”

Skill development training on Instrumental jute grading as per NABL requirements

FLD cum Training Programme on Retting, and Bleaching & Dyeing of Nettle Fibre

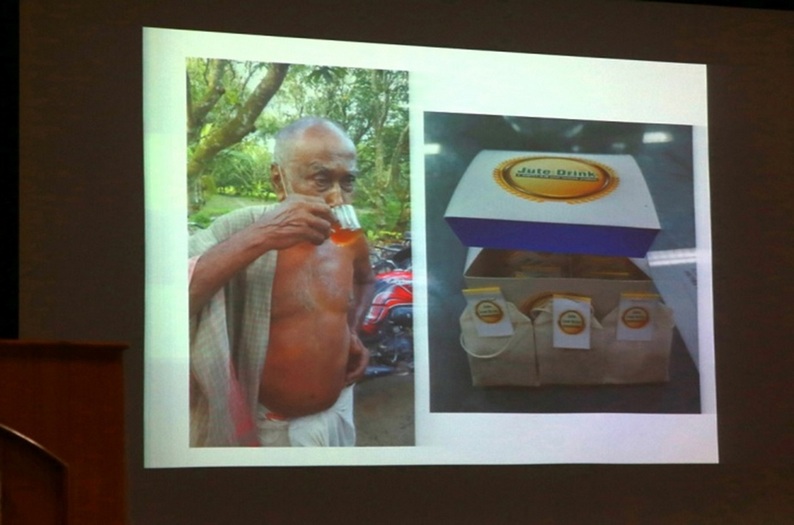

Workshop on Production Jute Leaf Drinks

Exposure Visit of the Students of IRDM Faculty Centre

ICAR-NINFET organized World Environment Day, 2023

Skill development training programme on “Bleaching and Dyeing of Jute”

Inauguration of Self-Sponsored training programme on “Bleaching and Dyeing of Jute” for prospective entrepreneurs

Awareness cum Sensitization Programme of ICAR activities at M H M School, Kolkata

Skill development programme on “Manufacturing of jute handicraft and jute ornaments”

RAC Meeting, 2023

RAC Meeting, 2023

Product Development from Kans Fibre at Manikpur

DG, ICAR visit at Krishi Mela at RKM, Sargachi

Shri. Biplab Roy Chowdhury, Minister of Fisheries, Govt. of West Bengal visited NINFET stall at RKM Sargachi, Murshidabad during Krishi Mela

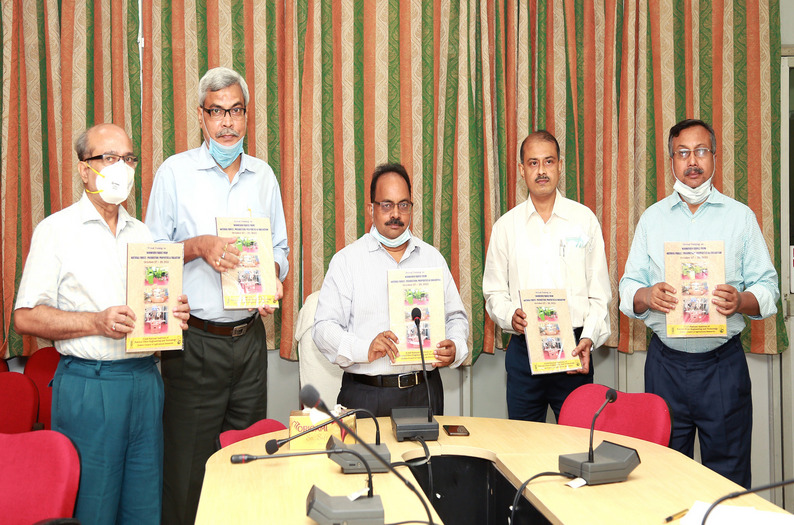

National conference organized by ICAR-NINFET, Kolkata

National conference organized by ICAR-NINFET, Kolkata

National conference organized by ICAR-NINFET, Kolkata

National conference organized by ICAR-NINFET, Kolkata

National conference organized by ICAR-NINFET, Kolkata

National conference organized by ICAR-NINFET, Kolkata

ICAR-Sponsored Winter School, 2023

ICAR-Sponsored Winter School, 2023

21 days ICAR-Sponsored Winter School

Brainstorming Workshop organized at ICAR-NINFET

आईसीएआर-निनफेट, कोलकाता में "विज्ञान और किसान: भारत@75" पर हिंदी संगोष्ठी का आयोजन

"विज्ञान और किसान: भारत@75" पर हिंदी संगोष्ठी के अवसर पर डॉ. एस.एन. झा, उप महानिदेशक (कृषि अभियंत्रकी) व्याख्यान देते हुए

Programme on Mass Media Campaign and Nation Wide Campaign on Potential of Natural Fibre for Replacement of Single-use Plastic

Programme on Mass Media Campaign and Nation Wide Campaign on Potential of Natural Fibre for Replacement of Single-use Plastic

Institute-Exemployee interface

Training Programme on “Objective Quality Evaluation of Jute and Other Lignocellulosic Fibres”

Industry-Institute Interface on Vision@2047

Industry-Institute Interface on Vision@2047

Sectorial Campaign on “Processing & Value Addition of Jute Fibre” Organized

Sectorial Campaign on “Processing & Value Addition of Jute Fibre” Organized

One-day Seminar on Futuristic Approaches on Natural Fibres

Interface Meeting with NABARD

Workshop on Commercialization of Yak based products

73rd IMC meeting of ICAR-NINFET

Workshop on “Women Empowerment and Technopreneurship on Health, Hygiene and Environment”

Quality Improvement Programme

Skill Development Training on Jute Handicrafts, 2022

Training Programme on “Quality Management System as per ISO 90012015”

On-campus programme and live streaming of PM Kisan Samman Nidhi Fund Release

On-campus programme and live streaming of PM Kisan Samman Nidhi Fund Release

Training Programme in collaboration with MANAGE on Value Chain Management in Natural Fibres

Training Programme in collaboration with MANAGE on Value Chain Management in Natural Fibres

Industry-interaction program on Jute Geotextiles

Training Programme on “E Office & ERP for Administrative Staff”

Seminar on “Sustainable Textiles – Standards and Regulations”

one day workshop on Scope of Entrepreneurship Development in Yak Based Products

One day workshop on Scope of Entrepreneurship Development in Yak Based Products

ICAR-NINFET organized Entrepreneurship Development Programme

ICAR-NINFET organized Entrepreneurship Development Programme

Training programme on ‘Nonwoven Fabric from Natural Fibres: Production, Properties and Evaluation’

Vigilance Pledge at ICAR-NINFET, Kolkata

Hindi Scientific Seminar under the theme, “भारत का अमृत महोत्सव - आत्मनिर्भर भारत की ओर बढ़ते कदम”

Hindi Scientific Seminar under the theme, “भारत का अमृत महोत्सव - आत्मनिर्भर भारत की ओर बढ़ते कदम”

National Level Campaign on “Food and Nutrition for Farmers” @ Azadi Ka Amrut Mahotsav

National Level Campaign on “Food and Nutrition for Farmers” @ Azadi Ka Amrut Mahotsav

Observation of 16th Parthenium Awareness Week

One-Day Workshop on Importance of Handloom in The Society and Economy

Workshop on Fibre Grading Instruments

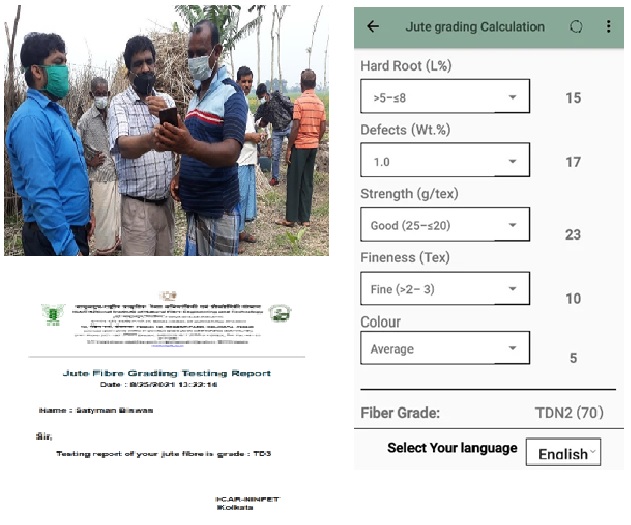

Jute grading calculation using Institute Mobile App and certificate generation at farmer field

Celebration of Bharat ka Amrut Mohotsav by ICAR-NINFET

Celebration of Bharat ka Amrut Mohotsav by ICAR-NINFET

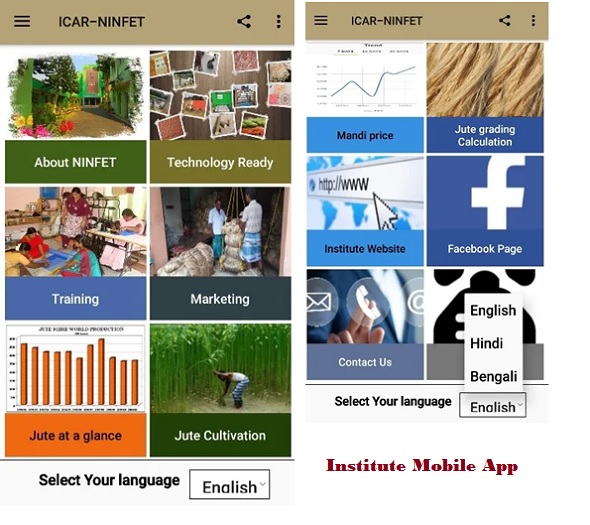

ICAR-NINFET Mobile App

Closing Ceremony of 150th Birth Anniversary of Mahatma Gandhi

Interface Meeting with farmers, Dirang, Arunachal Pradesh

Training programme on “Manufacture of Jute Handicrafts”

Technology and Machinery Demonstration Mela

Training Programme on Advanced Jute Handicrafts

Technology and Machinery Demonstration Mela